As the 2020 COVID‐19 pandemic unfolds, the tremendous emphasis has been focused on food supply chains becoming robust in a time of crisis. Food supply chains have had to adapt rapidly to demand shocks, including panic purchasing and shifts in food buying patterns, as well as to prepare for any supply disruptions due to possible labor shortages and transportation and supply network interruptions [43]. Every bit of the food industry has been shaken in some way with losses being experienced by all stakeholders including the consumers.

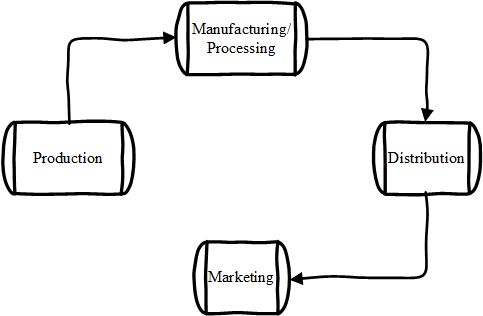

The food industry is made up of four key sectors:

- Production – Produces raw materials for industries. It includes farming, ranching, aquaculture, fishing, and orchard management.

- Manufacturing – Converts raw agricultural materials to more refined or finished products. Requires many input operations and processes that are key in ensuring food quality and safety.

- Distribution – Concerns itself with aspects that are conducive to product sales e.g. storage stability, storage requirements, product form, weight, bulk, and transportation.

- Marketing – Selling of food and food products; wholesale, retail, restaurants, institutional, etc.

Production

COVID-19 outbreak has tested the resilience of the agricultural sector in many ways. The agricultural sector is tasked with providing food directly to the retailers and consumers as well as inputs for many manufacturing companies. COVID-19 has impaired operations in several ways:

1. Food losses

There have been huge losses of food especially because of the impairment of the transport sector. Food spoilage has been reported as tracks carrying food products destined for the farmers market or the manufacturing industries got stuck on the roads due to long queues generated by the need to test drivers on the move to avoid the spread of infections. Since the tests are not instant, drivers have had to stay on the road longer with produce ending for the waste bin.

Since farmers cannot stop the “biological clock” for their produce that is on the farm, major losses have also been experienced on the farms as farmers are cut from accessing the market. Nevertheless, allowing free movement for the transporters of fresh produce has seen the production sector survive some of these hurdles.

2. Difficulties accessing farm inputs

Access to farm inputs is also a problem. Due to huge losses in income, some farmers may find it difficult to return to their farms if they are unable to purchase the inputs. COVID-19 has also caused impairment in the supply chains which has created a surge in demand for some of these inputs. As anticipated, the cost of some of these inputs may go up further making it hard for the farmer to access.

3. Reduced workforce

Due to the implementation of travel restrictions in some places, workers are unable to access the farms which further impairs the efforts of the farmer in trying to stay afloat amidst the coronavirus pandemic. Even for the workers who may show up for work, the farmer has to implement certain protocols to ensure sufficient social distancing and hygiene for the workers. Social distancing at work means cutting down on the number of workers on the farm at any time and disinfecting the facility after every shift. All these have slowed down operations which may potentially lead to a reduction in production.

Manufacturing

The manufacturing sector relies on the production sector for their inputs. COVID-19 has impaired the operations in several ways:

1. Problems accessing inputs

Due to the slowed operations at the production level, manufacturers have had to also slow down their operations. If it becomes impossible for the farmer to transport produce to the factory, the manufacturer may have to close down operations. Besides, the reception of the raw materials has had to change to allow for social distancing and hygiene and sanitation for any farmers delivering inputs to the factories. This has slowed down operations even for those manufacturers who have not lost their supply.

2. Reduced production capacity

Due to slow down operations, some manufacturers may not meet their supply requirements which will ultimately affect the production for other companies that rely on inputs from this company. This contributes to the loss of profits and income for many in the manufacturing industry.

3. Reduced workforce

Some factories have had to lay off some of their operators to be able to maintain the social distance at the workplace or due to loss of inputs. This further contributes to the loss of income for the manufacturer.

Distribution

Distribution channels have been impaired by the coronavirus pandemic in many ways:

1. Closure of transport routes

Due to the ongoing travel bans, some destination sites have been rendered inaccessible after the closure of cities connecting the producer or manufacturer to the consumers. Alternatively, the transporters have had to find other routes that may take them longer to reach the market. This risks food spoilage during transportation which further contributes to food losses for the food industry.

2. Lockdown of destination sites

Although the transport of essential goods including food has not been prohibited, it takes longer to access areas under lockdown. Thus, the risk of food spoilage during transit is still high. Also, the risk of contracting COVID-19 for the transporter and shipping it back to their origin is high.

3. Long queues on the road

As mentioned earlier, food products, especially for the transporters who move across territories, have been greatly impaired as countries ban movement into their territories. Food on transit has spoiled as transporters wait to comply with guidelines including having been tested for COVID-19.

Marketing

At retail, the problems experienced down the chain are transmitted up the chain.

1. Reduced supplies

If produce never gets to the market, retailers have nothing to sell. This means that consumers also have nothing to buy. This creates an increase in demand which may spike the cost of products making it harder for the consumer. This means huge losses are being incurred by retailers.

2. Changing consumer buying patterns

Consumers buying patterns have changed. Like in the case of the foodservice industry, some consumers may opt to prepare their food than sit and order food from a hotel for fear of contracting the disease. This has resulted in huge losses even for those in foodservice. Panic buying has also been witnessed causing a surge in demand for essential products. This means that some consumers have had to do without some of these necessities.

3. Closure of businesses by the government

Closure of foodservice outlets has to lead to huge losses of income for workers who have been laid off and for the hotel owners. Even after reopening, the guidelines provided by the government for them to comply with have seen some of them fail to reopen.

Generally, everyone in the food chain is feeling the pinch of the coronavirus pandemic. Everyone has had to readjust, let go of some habits and learn a few other things. Going forward, it is the most resilient of the actors who may be in business when this pandemic subsides.

Although most of the sectors have been negatively affected, a few have benefited from increased sales:

- Those involved in-home delivery services have seen a surge in demand for goods as people prefer to stay indoors and order stuff online.

- Framers close to the market have benefited due to the increase in demand and direct sales to the consumers of their goods.

Way forward for the food industry

Recovery time for many manufacturers will be long and therefore, the lessons learned from the coronavirus pandemic must be remembered for generations to come to ensure that improvements are put in place. The future must take into consideration the hurdles that the food industry has had to confront.

The food industry has to work and anticipate that such occurrences such as the coronavirus may impair the systems in the future. Modalities to keep systems operational have to be put in place going forward. This means that we will need to build a sustainable food supply chain for the future.

The need to work from home has become a reality for many manufacturers. Such systems have to also be explored to make sure that in the future, it is only those who must be physically available at the factory who are working from the factory.

Perhaps, a quantification of food losses due to corona virus pandemic as well as the loss in income for actors in the food chain is needed to assess the damage caused to the food industry.

Research needs