Food quality assurance refers to the systematic processes and procedures implemented by food companies to ensure that their products meet specific quality standards and are safe for consumption. It involves various measures to control and monitor the quality of raw materials, production processes, and finished products.

Key elements of food quality assurance

Here are some key elements of food quality assurance:

- Quality Control: Implement quality control measures to monitor and test raw materials, ingredients, and finished products. This includes sampling, laboratory testing, sensory evaluation, and compliance with regulatory standards. Quality control ensures that products meet specific criteria for taste, appearance, texture, nutritional content, and safety.

- Standard Operating Procedures (SOPs): Develop comprehensive SOPs for each stage of the food production process. SOPs outline specific procedures, protocols, and best practices to ensure consistency and quality. They cover areas such as sanitation, hygiene, handling of raw materials, processing methods, equipment calibration, and packaging.

- Good Manufacturing Practices (GMP): Adhere to GMP guidelines, which provide a framework for maintaining high standards of cleanliness, hygiene, and safety in food production facilities. GMP covers areas such as facility design, equipment maintenance, personnel training, sanitation, pest control, and documentation.

- Hazard management: Implement a system to identify and control potential hazards in the food production process. For instance, Hazard Analysis and Critical Control Points (HACCP) involves conducting a thorough hazard analysis, determining critical control points, establishing control measures, monitoring procedures, and maintaining detailed records.

- Supplier Quality Assurance: Establish criteria and procedures to evaluate and select reliable and reputable suppliers. Conduct regular audits and inspections of suppliers to ensure they meet quality and safety standards. Maintain open lines of communication with suppliers to address any quality-related issues promptly.

- Training and Education: Provide regular training and education programs for employees to enhance their understanding of quality assurance principles and practices. This includes training on GMP, HACCP, food safety, hygiene, and handling practices. Well-trained employees are essential for maintaining quality standards and identifying potential risks.

- Documentation and Record Keeping: Maintain detailed records of all quality-related activities, including test results, inspection reports, supplier certifications, training records, and customer feedback. This documentation serves as evidence of compliance and provides a reference for continuous improvement.

- Continuous Improvement: Establish a culture of continuous improvement by regularly reviewing and evaluating quality assurance processes. Analyze data, customer feedback, and industry trends to identify areas for improvement and implement corrective actions. This includes regular internal audits, management reviews, and participation in external quality assurance programs.

- Regulatory Compliance: Stay updated with relevant food safety regulations and standards applicable to your industry. Ensure compliance with regulatory requirements, such as labeling regulations, allergen management, product testing, and recall procedures. Regularly review and update procedures to align with changing regulations.

- Consumer Feedback and Complaint Handling: Establish mechanisms to collect and respond to consumer feedback, complaints, and inquiries. Implement a robust system for handling and investigating complaints, taking corrective actions, and communicating with customers. This helps in identifying potential quality issues and maintaining customer satisfaction.

By implementing these elements of food quality assurance, food companies can establish and maintain high-quality standards, ensure product safety, and build trust with consumers.

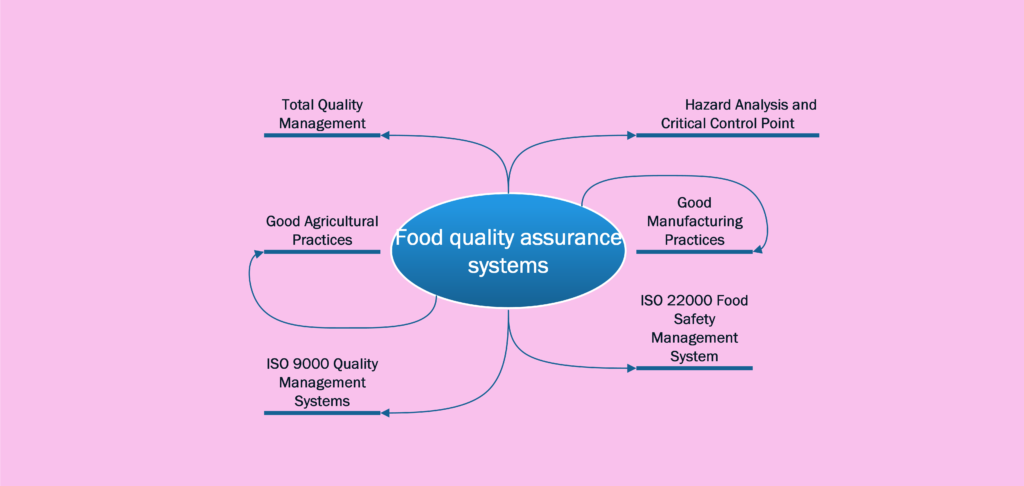

Important quality assurance (QA) systems

A number of quality assurance (QA) systems are available to the food industry such as

- GMP (Good Manufacturing Practices),

- HACCP (Hazard Analysis and Critical Control Points), and

- ISO (International Organization for Standardization) standards such as ISO 9000 (Quality Management System) or ISO 22000:2005 (Food safety management systems – Requirements for any organization in the food chain).

For food quality and health control these programs and their combinations are recommended. The production of agri-food requires a particular approach for achieving the desired level of quality. It is crucial to know how much the programs relate to the overall product output and to align the resources used to achieve the quality and safety goals [12].

Food safety knowledge is for all!

Every consumer deserves to have high quality and safe food. …Read more!

A quality management system (QMS) system can be defined as: a set of coordinated activities to direct and control an organization in order to continually improve the effectiveness and efficiency of its performance [12].

According to Rotaru and others [12], the QMS can be categorized according to the extent of activities they cover:

- basic safety systems: prerequisites (GAPs, GMPs, GLPs, etc.);

- advanced safety systems such as HACCP;

- integrated food safety management – ISO 22000;

- basic quality management systems – ISO 9001;

- advanced quality management systems – ISO 9004

Prerequisite programs

These are programs that are required as a prior condition for other systems to exist and work effectively. A good example is the Good Manufacturing Practices (GMPs) which are the minimum sanitary and hygiene requirements for food producers. GMP recommendations are not formalized directives on how to manufacture goods. These are a set of general concepts to be followed during food production. See further discussion of Good Manufacturing Practices (GMPs), Good Agricultural Practices (GAPs) among others.

Hazard Analysis and Critical Control Points (HACCP)

HACCP is a systematic preventive, and proactive approach to food safety, focused on the identification and control of all biological, chemical and physical hazards from the processing of raw materials through the manufacture, distribution and consumption of the final product [12, 13]. The system is based upon seven principles:

- Principle 1: Conduct a Hazard Analysis

- Principle 2: Identify the Critical Control Points

- Principle 3: Establish Critical Limits

- Principle 4: Establish Monitoring Procedures for critical control limits

- Principle 5: Establish Corrective action procedures

- Principle 6: Verification of HACCP programme

- Principle 7: Effective record keeping and documentation

Basically, HACCP systems are designed to:

- Prevent hazards from occurring

- Eliminate any existing hazards completely

- Reduce any existing hazards to levels that are harmless to consumers making the food safe.

ISO 9001 Quality management systems — Requirements

The ISO 9001 belongs to a family of standards: ISO 9000 family of standards that are designed to assist organizations of all types and sizes, to implement and operate an effective quality management system.

- ISO 9000 describes fundamentals of quality management systems and specifies the terminology for quality management systems.

- ISO 9001 specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide products that fulfil customer and applicable regulatory requirements and aims to enhance customer satisfaction.

- ISO 9004 provides guidelines that consider both the effectiveness and efficiency of the quality management system. The aim of this standard is improvement of the performance of the organization and satisfaction of customers and other interested parties.

- ISO 19011 provides guidance on auditing quality and environmental management systems.

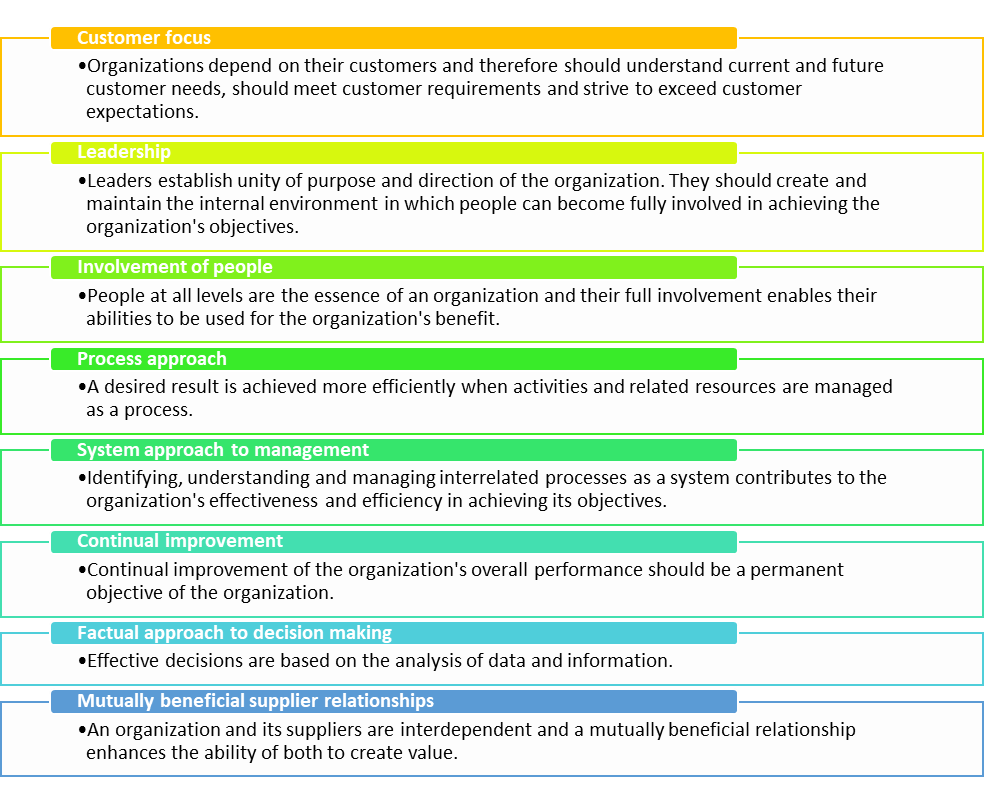

Eight concepts of quality management have been established which can be used by the top management to guide the company towards better results as shown in the figure below.

Read more about ISO 9000 standard here!

ISO 22000, Food safety management systems

ISO 22000, Food safety management systems – Requirements for any organization in the food chain, was first published in 2005. The standard provides international harmonization in the field of food safety standards, offering a tool to implement HACCP (Hazard Analysis and Critical Control Point) throughout the food supply chain.

The goal of ISO 22000 is to control, and reduce to an acceptable level, any safety hazards identified for the end products (An end product is defined as a product that will not undergo any further processing or transformation by the organization) delivered to the next step of the food chain.

Some highlights of ISO 22000 include:

- The establishment of prerequisite programs (PRPs),

- The identification and control of food safety hazards, and the determination of an acceptable level of risk

- The establishment of a HACCP plan

- The control of nonconformity in food products

- The establishment of a food safety team

- The establishment of a communications plan with external parties

- The establishment of a traceability system

Read more here: ISO 22000:2005 and ISO 22000: 2018

Some key advantages of implementing these systems include:

- recognition by international community

- marketing edge

- costs reductions

- Improved efficiency in processing

- Improved customer relations

Companies seeking to implement these systems should learn from others on difficulties that they would expect to encounter [14, 15]. It is however important to note that these systems are company or factory specific.

Our Blog ↗

Read the latest from our blog

Ask a Question ↗

Ask a question and get answers from our community

Give Feedback ↗

We value your feedback.

I was suggested this website by myy cousin. I’mnot

sure whetyher this post is written by him as nobody else knoow such

detailed about my difficulty. You’re wonderful! Thanks!

Feel free to visit my web blog; Agnes

Howdy are using WordPress for your site platform?

I’m new to the blog world but I’m trying to get started and create my own. Do you need any coding expertise to

make your own blog? Any help would be greatly appreciated!

Look at my site http://Ds-dealer.ru/forum/member.php?u=220010

I doo believe all of the ideas you’ve presented to your post.

They’re very convincing and will definitely work.

Still, the posts are too short forr novices.

May you please extend them a little from next time?

Thanks for the post.

My web blog … http://forum.ll2.ru/member.php?694007-Leonztx

Thanks for some other informative blog. Where else may just I am getting that type of info

writen in such an ideal method? I’ve a mission that I am simply noow running on, and I’ve been at the look out

for such info.

My homepage – http://anoreksja.org.pl/viewtopic.php?f=20&t=1000575

I seldom leave a response, but i did a few searching aand wound

up here An overview of food quality assurance (QA) systems – Ask The Food Scientists.

And I do have some questions for you if it’s allright.

Could it be just mme or does it look like a few of the remarks come acrross

like they are left by brain dead folks?:-P

And, if you are posting on additional online social sites, I would like to keep up with everything fresh you have to post.

Would you list of all of your communal sites like your linkedin profile, Facebook page or twitter feed?

Visit my blog post ::http://tsxvresearch.com/forum/viewtopic.php?f=3&t=140334

I think this is one of the most vital information for me.

And i’m goad reading your article. But want to remark on some general things,

The website style is wonderful, the artiicles is really great :

D. Good job, cheers

Here is my web-site http://www.victoriarabien.ugu.pl

Woah! I’m really loving thee template/theme of this blog.

It’s simple, yet effective. A lot of times it’s hard

to get that “perfect balance” between superb usability and visual appeal.

I must say you’ve done a excellent job with this.

In addition, the blog loads extremelyy fast for me on Firefox.

Superb Blog!

Take a look at my web site :: http://www.Jeepin.com/forum/member.php?u=116916

I have been exploring for a bit for any high-quality articles or weblog posts in thijs kind of house .

Exploring in Yahoo I at lasxt stumbled upon this webb site.

Studying this information So i am sayisfied too convey that I’ve an incredibly excelleent uncanny feeling I came upon exactly what I

needed. I such a lot for sure will make certain to don?t overlook this site and provides iit a glance regularly.

my blog – p68427

Hi! I simply would like tto give you a bigg thumbs up for your great information you’ve

got right here on this post. I will be retudning

to your site forr more soon.

my web site: http://www.glaschat.ru/glas-f/member.php?319375-Julibrn

I believe that is among the most vital info forr me.

And i am happy studying your article. But want to remark on ffew basic issues, The web site taste is great, the articles is really excellent :

D. Good process, cheers

Feel free to surf to myy weeb page http://Forum.d-dub.com/member.php?841814-Juliwii

You actually make it seem so easy with your presentation but I find this matter to be

really something that I think I would nevsr understand.

It seems too complicated and extremely broad for me.

I am looking forward for your next post, I will try too get tthe hang of it!

my page … Carmine

[…] за який місяць вона нарахована, Carmine – за попередній (у квітні за березень тощо) або ж за […]

priligy premature ejaculation pills Combination goserelin and tamoxifen therapy in premenopausal advanced breast cancer a multicentre study by the ITMO group

I think the admin of this web page is in fact working hard in favor of his website,

for the reason that here every information is

quality based material.