Slaughter of poultry and animals refers to the process of humanely and efficiently ending the lives of these animals for food production. The primary objectives of slaughter are to ensure food safety, animal welfare, and product quality. The process typically involves several key steps.

Poultry slaughter

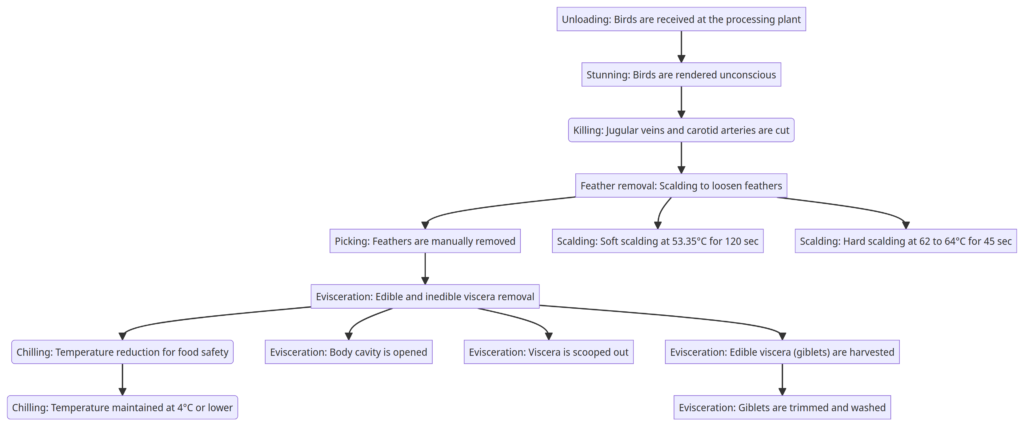

Key steps in the slaughter process:

Unloading: Upon arrival at the processing plant, the birds are unloaded for further processing. Workers attach the animals onto moving rails.

Stunning: The initial step in humane slaughter is the process of “stunning,” which renders the bird unconscious prior to killing. Electric shock is commonly used, where the birds’ heads come into contact with a saline solution (approximately 1% NaCl) that carries an electric charge. This renders the animal unconscious for a duration of 60 to 90 seconds.

Food safety knowledge is for all!

Every consumer deserves to have high quality and safe food. …Read more!

Killing: Following stunning, the bird is transported on a shackle conveyor to the killing machine. The jugular veins and carotid arteries are cut to allow bleeding and induce death.

Feather removal: This step involves scalding, which loosens the feathers. It is accomplished by immersing the carcasses in a hot water bath, which denatures the protein structures holding the feathers in place.

Two common methods are used for scalding:

- “Soft scalding” is performed at a temperature of 53.35°C (128°F) for 120 seconds.

- “Hard scalding” is carried out at a temperature of 62 to 64°C (145 to 148°F) for 45 seconds.

Picking: Picking is the process of removing the feathers from the bird’s body.

Evisceration: Evisceration involves the removal of both edible and inedible viscera from the carcass. It serves three main objectives:

- Opening the body cavity by making a cut from the posterior tip of the breastbone to the cloaca (anus).

- Scooping out the viscera, including the gastrointestinal tract, reproductive tract, heart, and lungs.

- Harvesting the edible viscera or “giblets” (heart, liver, and gizzard) from the extracted viscera, trimming them of adhering tissues, and washing them with water.

Chilling: The primary purpose of chilling poultry is to reduce microbial growth to a level that ensures optimal food safety and allows sufficient time for marketing. Typically, a temperature of 4°C or lower is achieved as soon as possible after evisceration (within 1 to 2 hours postmortem).

Animal slaughter

Cattle

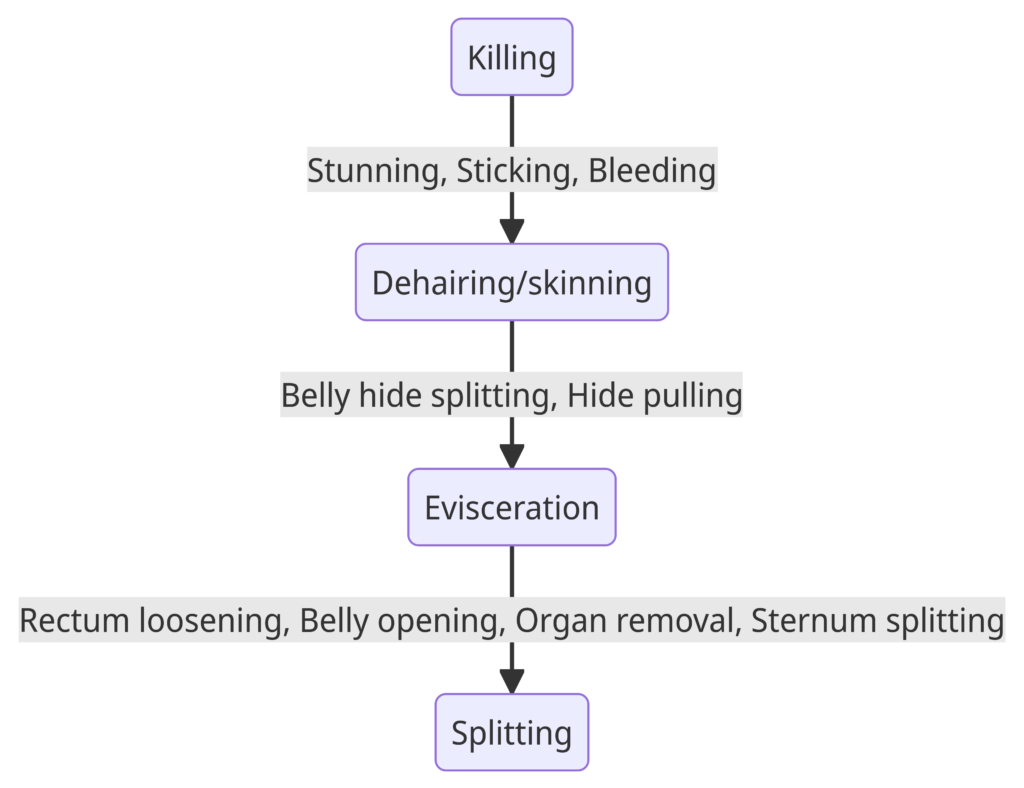

Summary of the steps:

Killing:

- Stunning: The animal is rendered unconscious to ensure a humane process.

- Sticking: Involves severing major blood vessels to allow bleeding.

- Bleeding: Ensures the removal of blood from the carcass.

Skinning:

- Belly hide splitting: The hide on the belly area is divided for further processing.

- Hide pulling: The hide is pulled off the carcass.

Evisceration:

- Rectum loosening: The rectum is loosened to facilitate its removal.

- Belly opening: The belly area is opened to access the internal organs.

- Organ removal: Involves the removal of internal organs from the carcass.

- Sternum splitting: The sternum is split to separate the ribcage.

Splitting:

- Backbone splitting: The backbone is divided into smaller sections.

- Grading and inspection: The carcass is evaluated for quality and inspected for any defects.

- Chilling: The carcass is cooled to maintain proper temperature for preservation.

- Carcass break-up: The carcass is broken down into various cuts and sections.

- Primalization: The carcass is segmented into primal cuts, such as chuck, loin, and rib.

- Boning: The bones are removed from the meat.

- Trimming: Any excess fat or undesirable portions are trimmed from the meat.

Note: Slaughter of poultry and animals must be done in a humane manner to ensure that the animals are treated with respect and dignity throughout the process. Humane slaughter practices aim to minimize pain, stress, and suffering for the animals. This includes the use of effective stunning methods to render the animals unconscious and insensible to pain before any further steps are taken. By ensuring a quick and efficient stunning process, animals are spared from unnecessary pain and distress.

Pigs – Pork

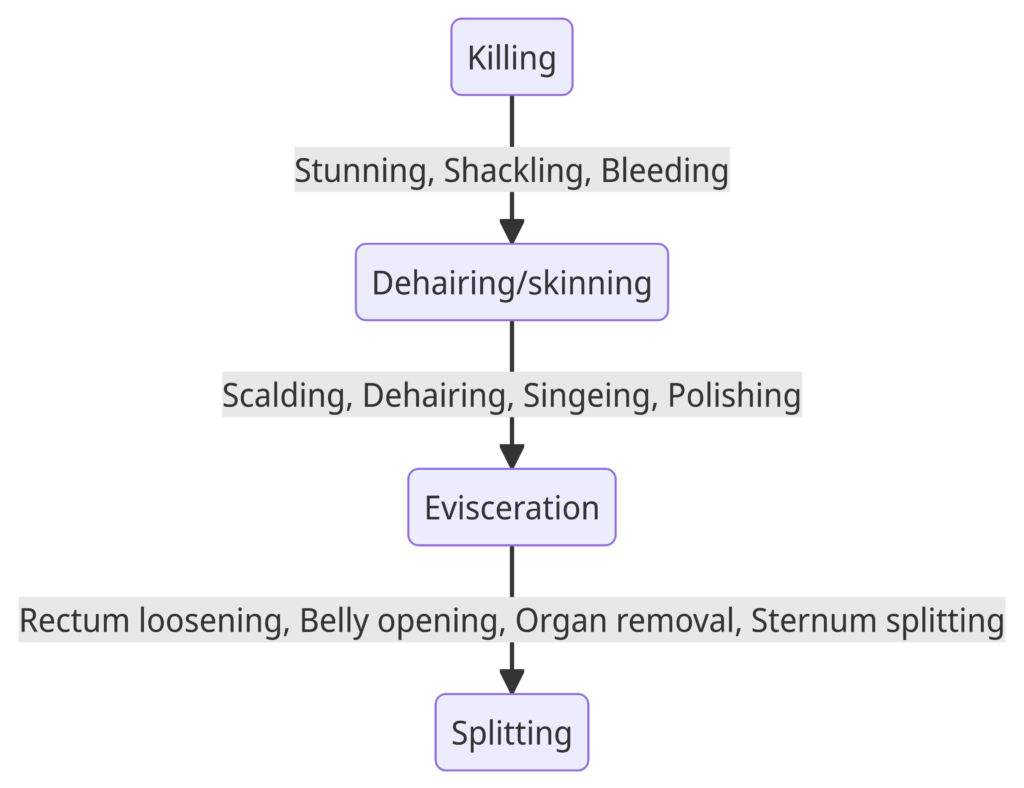

Summary of the steps:

Killing:

- Stunning: The animal is rendered unconscious to ensure a humane process.

- Shackling: The animal is restrained by attaching it to a moving rail.

- Bleeding: Ensures the removal of blood from the carcass.

Dehairing:

- Scalding: The carcass is immersed in hot water to loosen the hair for easier removal.

- Dehairing: Involves mechanically removing the loosened hair from the carcass.

- Singeing: The surface of the carcass is exposed to flames to remove any remaining hair or bristles.

- Polishing: The carcass is polished to achieve a smooth and clean appearance.

Evisceration:

- Rectum loosening: The rectum is loosened to facilitate its removal.

- Belly opening: The belly area is opened to access the internal organs.

- Organ removal: Involves the removal of internal organs from the carcass.

- Sternum splitting: The sternum is split to separate the ribcage.

Splitting:

- Preparation: The carcass is prepared for further processing, such as trimming and portioning.

- Backbone splitting: The backbone is divided into smaller sections.

These explanations provide a general understanding of the substeps involved in each major step of the pork processing.

It is important to note that during the slaughter of poultry and animals process, strict adherence to food safety and animal welfare standards is essential to ensure the production of safe and high-quality meat products while maintaining ethical practices.

Our Blog ↗

Read the latest from our blog

Ask a Question ↗

Ask a question and get answers from our community

Give Feedback ↗

We value your feedback.

fda approved canadian online pharmacies

canadian prescription

buy drugs canada

most reliable online pharmacy

cheap drugs online