Parboiling is a cooking technique that involves partially boiling food items, usually grains or vegetables, before finishing the cooking process using another method such as baking, frying, or steaming. The term “parboil” comes from the words “partial” and “boil.”

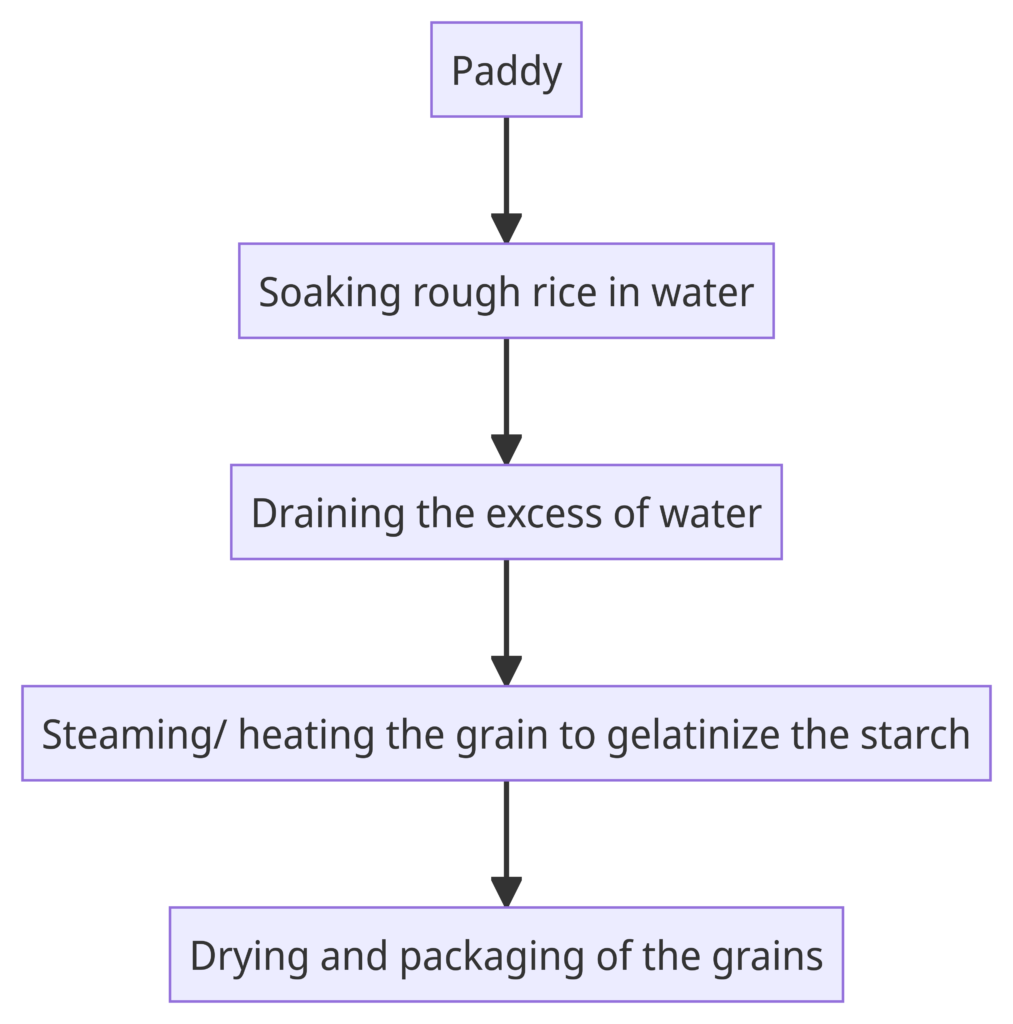

Parboiling is a hydrothermal treatment of rice grain at atmospheric pressure that involves three main steps: soaking of paddy in hot water below its gelatinization temperature, steaming the hydrated paddy and drying to 12–14% moisture content

Kumar et.al., (2022)

How parboiling is done

In an industrial setting, the pre-cooking process involves the separate application of water and heat to prevent excessive absorption and the risk of the rice kernel bursting or losing its shape.

In practical terms, the procedure entails immersing rough rice in water until it becomes fully saturated, removing any surplus water, and then subjecting the grain to steaming or alternative heating methods to achieve starch gelatinization. The grains are subsequently dried and packaged as shown below.

What happens during parboiling?

- Gelatinization of starch granules: Parboiling causes the starch granules in rice to undergo gelatinization, leading to changes in the rice kernel’s overall quality parameters.

- Structural properties of rice starch: Parboiling alters the structural properties of rice starch, converting it from a crystalline form to an amorphous form. This results in a highly compact and translucent endosperm.

- Increased levels of resistant starch (RS): Parboiling increases the levels of resistant starch in rice. Resistant starch reduces starch digestibility, which is reflected in lower glycemic index (GI) and glycemic load (GL) values of parboiled rice.

- Increased iron (Fe) content: Parboiled rice has been reported to have higher iron content compared to non-parboiled rice. This increase may be due to the diffusion of iron from the outer layer of the rice grain into the endosperm during parboiling.

- Improved storage stability: Parboiling rice is also an economical way to improve the storage stability (reduction of insect infestation)

- Results in significantly increase the nutritive value of the rice: during the parboiling treatment, vitamins and minerals seep into the endosperm from their natural place of residence in the bran and aluerone layer. Thus, post-milling parboiled rice contains much greater amounts of B vitamins, minerals (especially Ca, P, and Fe), and free amino acids than raw rice.

- Reduction in nutrient loss: the loss of nutrients during washing is also greatly reduced.

- Improved cooking quality: parboiled grains do not mash together after cooking, thus remaining whole, and making rice suitable for making products which are canned, expanded or flaked.

Disadvantages of parboiling

- High energy is required for the operation: The rice husk represents a hurdle for the entire parboiling process because it has a poor thermal conductivity resulting in increased time and heat energy required for wetting and heating.

- Longer duration of drying required: the husk is also a barrier during the drying operation after parboiling

- Rancidity: the final rice is more prone to oxidative rancidity. Rice milling

Our Blog ↗

Read the latest from our blog

Ask a Question ↗

Ask a question and get answers from our community

Give Feedback ↗

We value your feedback.