What is sugar?

Sugar is a sweet and crystalline substance that plays a significant role in our daily lives. It is one of the most widely used and consumed food ingredients worldwide. Known for its ability to enhance flavors, sugar is a key ingredient in a wide range of foods, beverages, and desserts. Sugar processing is done using two natural sources: sugar cane and sugar beets.

These plants contain natural sugars that are extracted and processed to produce the refined sugar we commonly use. Sugar cane is a tall grass-like plant mainly grown in tropical and subtropical regions, while sugar beets are root vegetables grown in temperate climates.

Sugar processing involves transforming sugar cane or sugar beets into refined sugar through several stages. In this article, we will explore the fascinating journey that takes place to bring the beloved table sugar into our hands. We’ll uncover the stages involved in transforming sugar cane or sugar beets into the refined sugar that we commonly use and enjoy.

Sugar comes in various forms, including granulated sugar, powdered sugar, and brown sugar. Each form has its own unique characteristics and uses in cooking, baking, and sweetening beverages.

Apart from its sweetening properties, sugar also contributes to the texture, color, and preservation of food products. It acts as a natural preservative and helps extend the shelf life of certain foods. Sugar also provides energy as a carbohydrate, though excessive consumption should be moderated as part of a balanced diet.

While sugar adds sweetness and enjoyment to our lives, it is important to consume it in moderation. Excessive sugar intake has been associated with health concerns such as obesity, dental issues, and chronic diseases. It’s advisable to be mindful of sugar consumption and make informed choices about overall dietary habits.

Food safety knowledge is for all!

Every consumer deserves to have high quality and safe food. …Read more!

Manufacture of sugar from sugar cane

Sugar cane, the raw material

Sugar cane is a tall perennial grass belonging to the Saccharum genus. It is primarily cultivated for the extraction of sugar from its fibrous stalks. Sugar cane is known for its high sugar content, making it a valuable crop for sugar production.

The plant grows in tropical and subtropical regions, thriving in warm climates with abundant rainfall. It can reach heights of 2 to 6 meters (6 to 20 feet) and consists of jointed stalks that contain sucrose, the main component of sugar.

Sugar cane cultivation involves planting cane cuttings or stalk sections in prepared soil. The plant takes approximately 10 to 18 months to reach maturity, depending on the variety and growing conditions. During this time, it undergoes photosynthesis, converting sunlight into energy and storing it as sugar in its stalks.

When the sugar cane reaches maturity, it is harvested by cutting the stalks close to the ground. The stalks are then processed to extract the juice, which contains the sugar. The juice undergoes various refining and purification steps to remove impurities and concentrate the sugar content.

The extracted sugar cane juice can be used to produce various forms of sugar, such as granulated sugar, brown sugar, and molasses. Additionally, sugar cane by-products like bagasse, the fibrous residue remaining after juice extraction, have various uses, including energy production, paper production, and as a raw material for certain industries.

In addition to its significance in the sugar industry, sugar cane is also cultivated for the production of ethanol, a biofuel used in transportation and as a renewable energy source.

Sugar cane is not only a valuable crop economically but also plays a role in providing employment opportunities for many communities around the world. It is a versatile and important plant that contributes to global sugar production and various other industries.

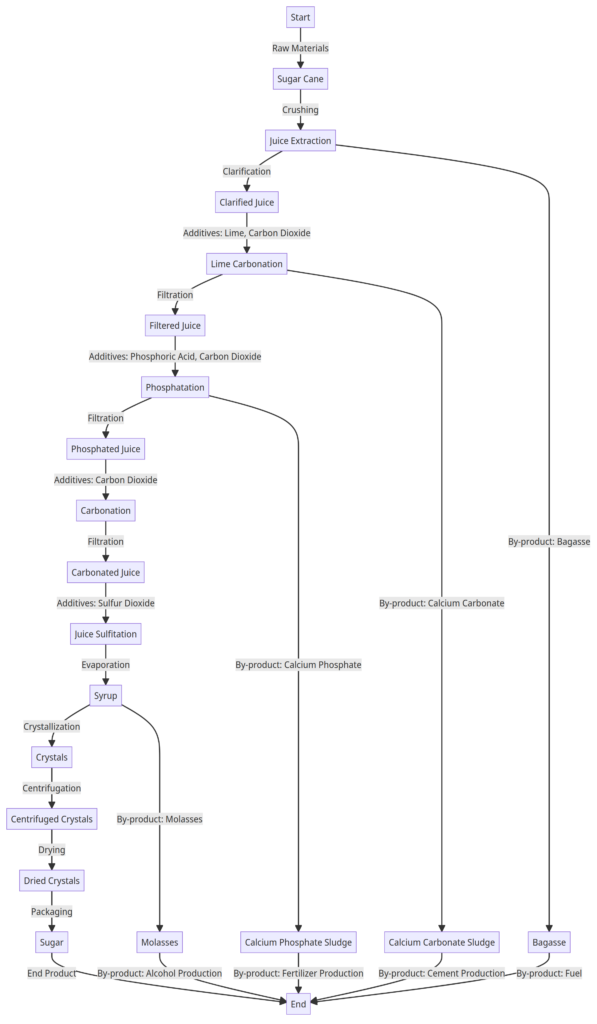

How sugar is processed from sugar cane

Here’s a brief explanation of each stage in sugar processing from sugar cane:

- Crushing: The sugar cane stalks are crushed to extract the juice. This stage breaks down the cane fibers and releases the juice.

- Juice Extraction: The crushed sugar cane is subjected to extraction to separate the juice from the solid fibers, commonly known as bagasse. The juice contains the sugars needed for further processing.

- Clarification: The extracted sugar cane juice is clarified to remove impurities such as dirt, suspended solids, and non-sugar components. This process helps improve the quality of the juice.

- Lime Carbonation: Lime (calcium hydroxide) and carbon dioxide are added to the clarified juice to adjust the pH and promote the precipitation of impurities. This process aids in further purification and clarification of the juice.

- Filtration: The carbonated juice is passed through filtration systems to remove any remaining solids and impurities. This step ensures a clear and clean juice for subsequent processing.

- Phosphatation: Phosphoric acid and carbon dioxide are added to the filtered juice to facilitate the formation of calcium phosphate crystals. These crystals trap additional impurities and aid in their removal during the filtration process.

- Carbonation: Carbon dioxide gas is introduced into the juice to form carbonic acid, which helps neutralize any excess lime and further remove impurities. This process also contributes to the formation of sugar crystals later on.

- Juice Sulfitation: Sulfur dioxide gas is used to treat the juice, preventing the growth of microorganisms and reducing color formation during subsequent processing stages.

- Evaporation: The treated juice is heated and concentrated through evaporation, which removes a significant portion of the water content. This step leads to the formation of syrup, which is rich in sugar.

- Crystallization: The concentrated syrup is cooled and agitated to promote the formation of sugar crystals. The crystals gradually grow in size as the syrup is continuously stirred.

- Centrifugation: The sugar crystals are separated from the remaining syrup through centrifugal force. The crystals, which are now referred to as raw sugar, are retained, while the remaining liquid, known as molasses, is separated.

- Drying: The centrifuged sugar crystals undergo a drying process to remove any residual moisture and achieve the desired moisture content. This step ensures the stability and quality of the sugar.

- Packaging: The dried sugar crystals are packaged into the final consumer-ready form, such as granulated, powdered, or cubed sugar.

By-products of sugar processing from sugar canes

- Bagasse: The fibrous residue left after juice extraction from sugar cane. It is commonly used as a biofuel or in the production of paper, animal feed, and other products.

- Calcium Carbonate Sludge: The precipitate formed during lime carbonation, which can be used in various applications such as cement production.

- Calcium Phosphate Sludge: The precipitate formed during phosphatation, which can be used as a fertilizer.

- Molasses: The thick, dark syrup remaining after sugar crystallization and centrifugation. It is often used in animal feed, fermentation for alcohol production, or further processing into molasses-based products.

These stages collectively transform sugar cane into refined sugar, while the by-products find various applications in different industries.

How sugar is processed from sugar beets

What are sugar beets?

Sugar beets are a type of root vegetable that belong to the Beta vulgaris species. They are grown specifically for their high sugar content, which makes them a valuable source of sugar production. Sugar beets are typically white or yellow in color and have a sweet taste.

These beets are grown in temperate climates and are cultivated primarily for commercial purposes. They have a higher sugar content compared to sugar cane, making them an important crop for sugar production in regions where sugar cane may not be suitable.

Sugar beets are harvested when they reach maturity, usually after about 90 to 120 days of growth. The beets are then processed to extract the sugar content, which undergoes further refining and purification to produce the refined sugar that is commonly used in cooking, baking, and sweetening various food and beverage products.

In addition to their sugar content, sugar beets are also a source of dietary fiber and contain essential nutrients such as vitamin C, iron, and potassium. They can be consumed as a vegetable, and their leaves, known as beet greens, are also edible and nutritious.

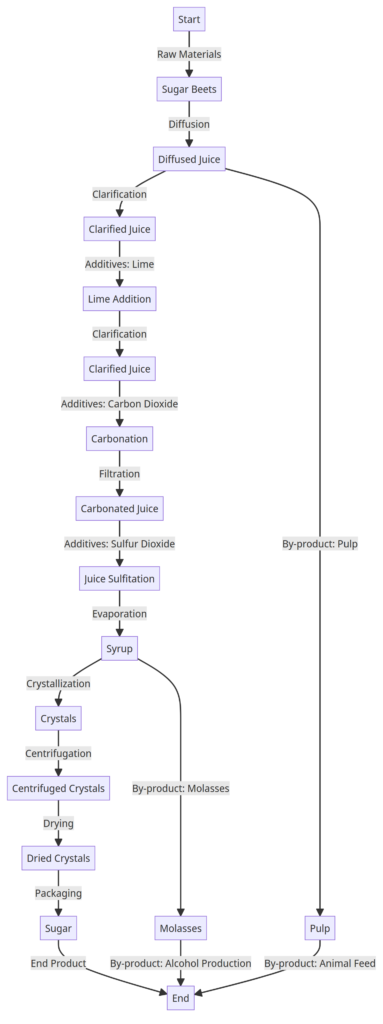

Extraction of sugar from sugar beets

Here’s a brief explanation of each stage in sugar processing from beets:

- Diffusion: Sugar beets undergo a diffusion process where they are sliced and soaked in hot water. This allows the sugar to dissolve and form a sugar-rich solution known as diffused juice.

- Clarification: The diffused juice is subjected to clarification to remove impurities and solid particles. This process helps improve the quality and clarity of the juice.

- Lime Addition: Lime (calcium hydroxide) is added to the clarified juice to adjust the pH and facilitate the precipitation of impurities. This step aids in further purification and clarification of the juice.

- Carbonation: Carbon dioxide gas is introduced into the juice to form carbonic acid, which helps neutralize excess lime and promote the precipitation of additional impurities. This process aids in further purification.

- Filtration: The carbonated juice is passed through filtration systems to remove any remaining solids and impurities, resulting in a clear and clean juice.

- Juice Sulfitation: Sulfur dioxide gas is used to treat the juice, preventing the growth of microorganisms and reducing color formation during subsequent processing stages.

- Evaporation: The treated juice is heated and concentrated through evaporation, which removes a significant portion of the water content. This step leads to the formation of syrup, which is rich in sugar.

- Crystallization: The concentrated syrup is cooled and agitated to promote the formation of sugar crystals. The crystals gradually grow in size as the syrup is continuously stirred.

- Centrifugation: The sugar crystals are separated from the remaining syrup through centrifugal force. The crystals, now known as raw sugar, are retained, while the remaining liquid, known as molasses, is separated.

- Drying: The centrifuged sugar crystals undergo a drying process to remove any residual moisture and achieve the desired moisture content. This step ensures the stability and quality of the sugar.

- Packaging: The dried sugar crystals are packaged into the final consumer-ready form, such as granulated, powdered, or cubed sugar.

By-products of sugar processing from sugar beets

- Pulp: The fibrous residue left after the diffusion process. It can be used as animal feed or further processed into other products.

- Molasses: The thick, dark syrup remaining after sugar crystallization and centrifugation. It is often used in animal feed, fermentation for alcohol production, or further processing into molasses-based products.

These stages collectively transform sugar beets into refined sugar, while the by-products find various applications in different industries.

References:

Delgado, A. V., & de Armas Casanova, C. (2001). Sugar processing and by-products of the sugar industry (No. 144). Food & Agriculture Org..

Duraisam, R., Salelgn, K., & Berekete, A. K. (2017). Production of beet sugar and bio-ethanol from sugar beet and it bagasse: a review. Int J Eng Trends Technol, 43(4), 222-233.

Akbar, A., & Ali, I. (2017). Value‐added by‐products from sugar processing industries. Food Processing By‐Products and their Utilization, 509-534.

Our Blog ↗

Read the latest from our blog

Ask a Question ↗

Ask a question and get answers from our community

Give Feedback ↗

We value your feedback.